Sustainable Sourcing

FIELDS products are crafted from natural fibres which are innately, breathable, biodegradable, durable and recyclable. The majority of our fibres are sourced in Southern Africa. South Africa's Merino Wool and Mohair are globally acclaimed for their exceptional quality and we are proud to showcase this through our products. FIELDS wool is Responsible Wool Standard (RWS) certified - this means that the sheep are ethically raised, mulesing-free, and graze on land that is progressively managed to protect soil health and biodiversity.

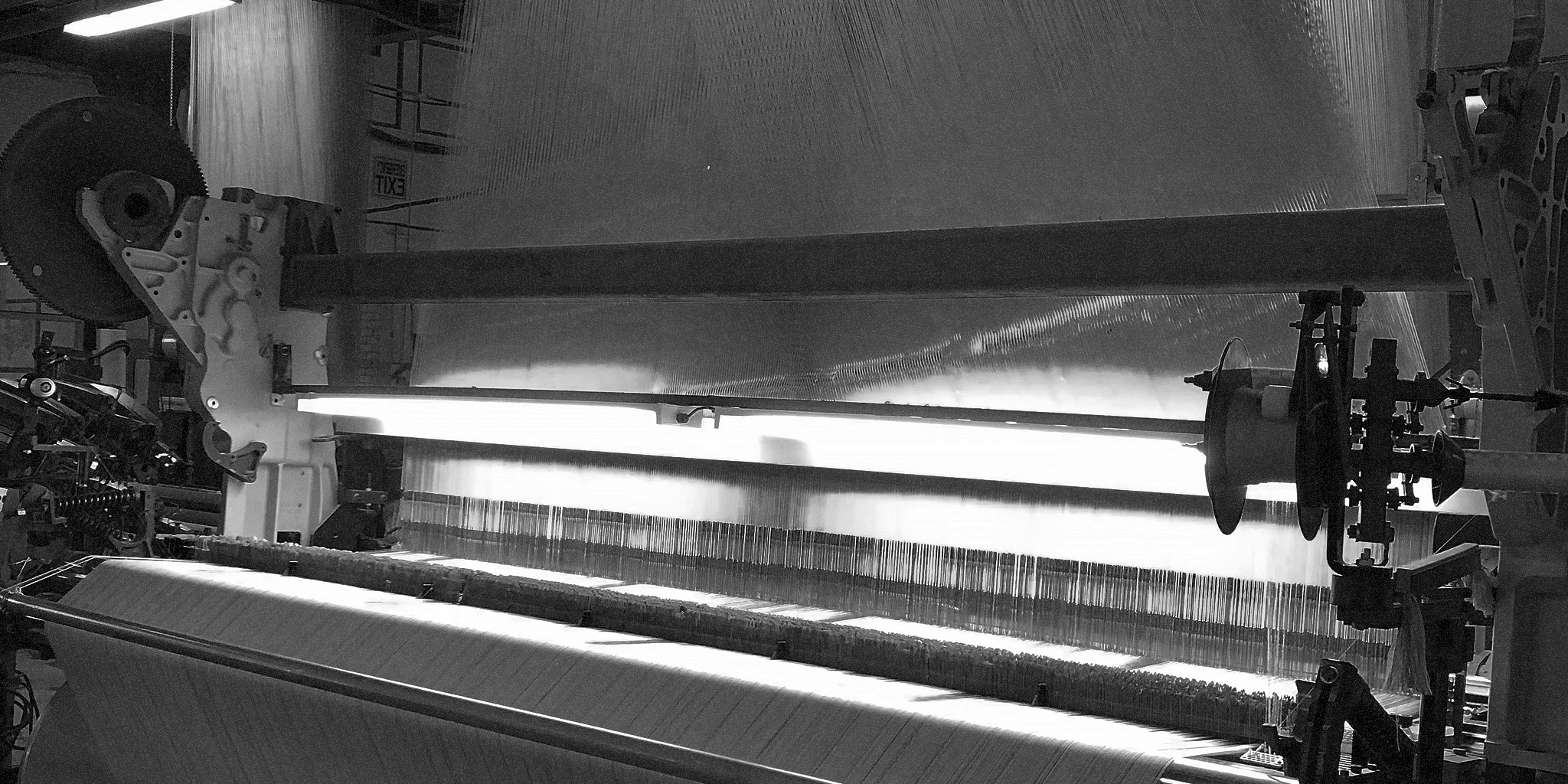

Weaving & Knitting

We take pride in selecting the highest quality fibres and textiles which are woven and knitted for FIELDS throughout Southern Africa and particularly the Western Cape of South Africa. In this process we have developed custom herringbone and twill weaves with a South African based mill, showcasing the quality our factory partners bring through their manufacturing. Regular collaboration with these partners is an integral part of the FIELDS process.

Cut, Make, Trim (CMT)

Our CMT partners are based in Southern Africa, with many in the Western Cape. It is here that the textiles are cut, sewn, pressed and finished before being delivered to our HQ Studio in Woodstock, Cape Town. This allows us to closely monitor quality, ensure production is on schedule, and minimise unnecessary transportation emissions. We work with specialist manufacturers and strive to achieve the best results. As an example, our trousers are made in a factory that only sews trousers and shorts - meaning their equipment, technique and execution are of a high standard. This theme of specialists continues to all elements of our production.

Our tote bags, which are made using our fabric off-cuts to minimise waste, are manufactured through a company that facilitates a network of previously disadvantaged sewing technicians as independent contractors, who are paid a good rate, are free to take on additional work, and all work from home using their own equipment eliminating the need for costly commutes.